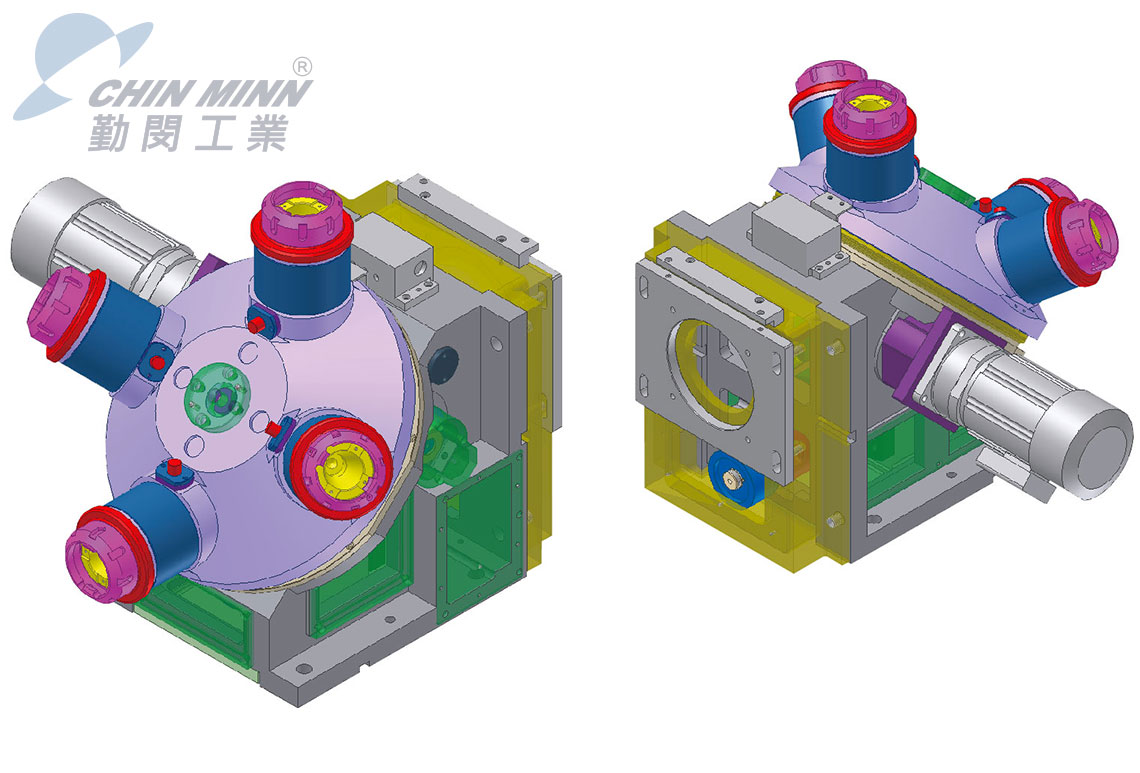

Product illustration of Centrifugal Separator (coolant filtering system)

Diagram of Centrifugal Separator (coolant filtering system):

Model: CL1-A

ChinMinn’s industrial centrifuge is designed and made for separating water based or oil coolant from iron scraps, metal chips, and non-magnetic particles. This coolant filtering system creates centrifugal force by spinning container, which particles and coolant will separate through centrifugal force. Later, cleaned fluid will drain out and separated sludge will stay inside the container. Lastly, filtered coolant gets to reuse.

The main purpose of coolant filtering is to separate particles from fluid. In addition, materials can be removed are not limited to ferrous; ChinMinn centrifuge works for non-ferrous materials as well, which included aluminum, stainless steel, silicon, graphite and any other materials that are heavier than fluid.

Three main points that make ChinMinn centrifuge different are: First, filter bags are not required for this filtration system. This centrifuge works without using consumption parts, which saves extra costs on buying additional items. It is an environment-friendly design for fluid and particles separation because it minimizes disposal volumes. Secondly, our machine is durable. Quality is guaranteed! Lastly, the most important point is the particles filtering capacity goes up to 95 percent of 10µ(micro size), which is precise and efficient!

~ChinMinn coolant centrifugal separating machine is an ideal product that fits your requirement:

no consumption parts, easy to clean, and efficient~

Specification:

| Item and Description | Specification |

| Main Motor | 5HP-4P |

| Process Volume | 80 L/MIN |

| Chip Material | Ferrous, Non-ferrous material, Silicon, and Graphite |

| Coolant type | Water based and oil |

| Application | Grinding machine coolant filtration |

| Filtering Capacity | Particles that can be removed are about: 70 percent of 5µ; 95 percent of 10µ |