Product Name : Heavy Duty Type Drawer Slides and Server Rack Slides Roll Forming Machine

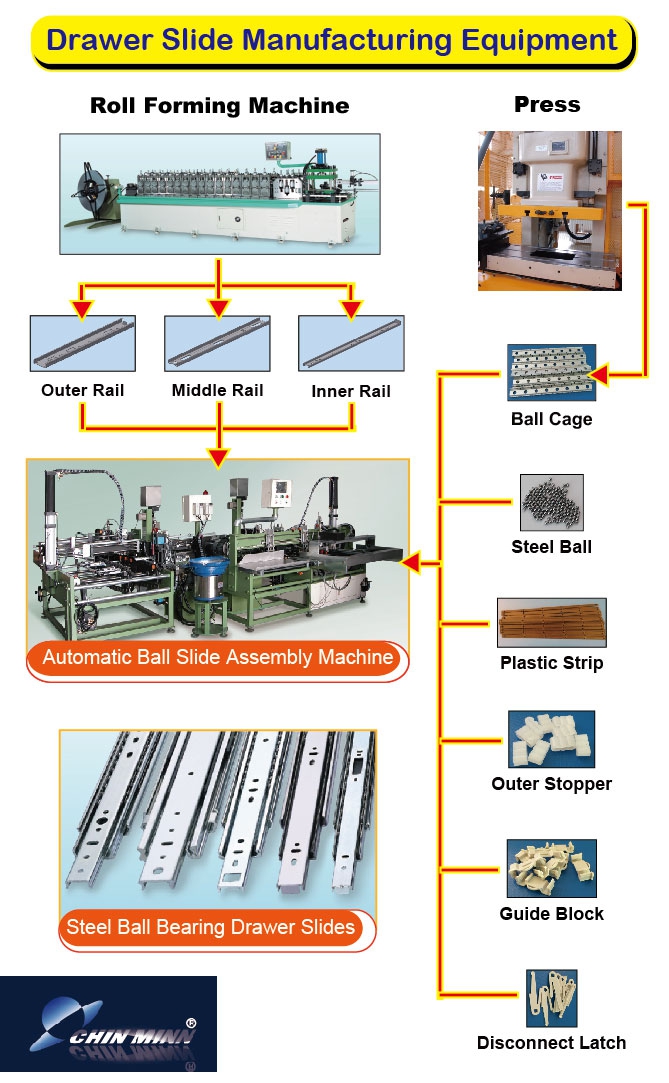

Manufacturing Process:

Uncoiling → Guiding → Roll Forming → Straightening → Hole Punch and Cut-off to length

Drawer slide machine Heavy duty type layout:

Description:

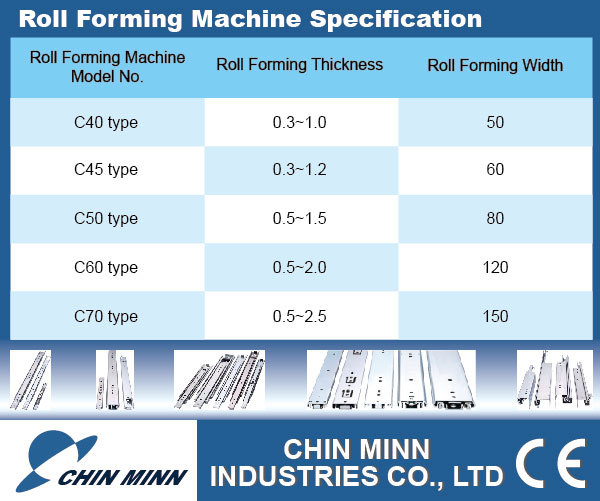

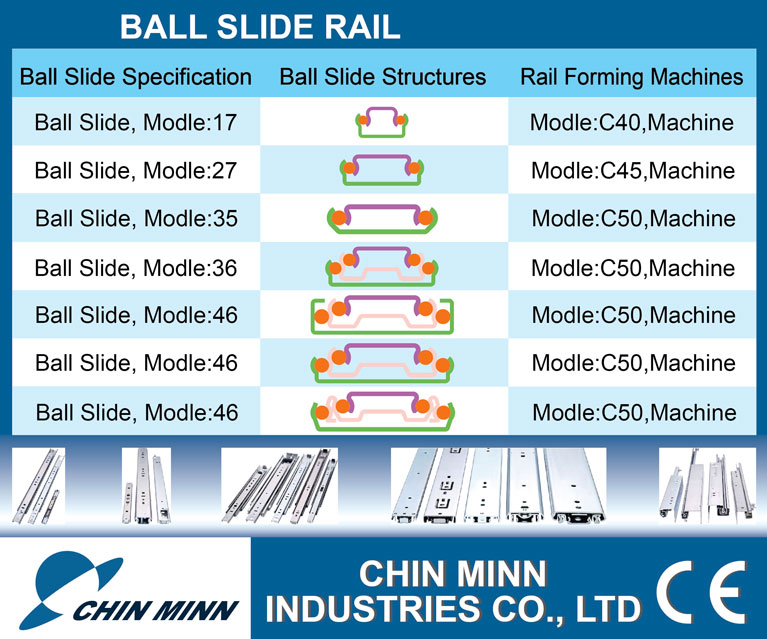

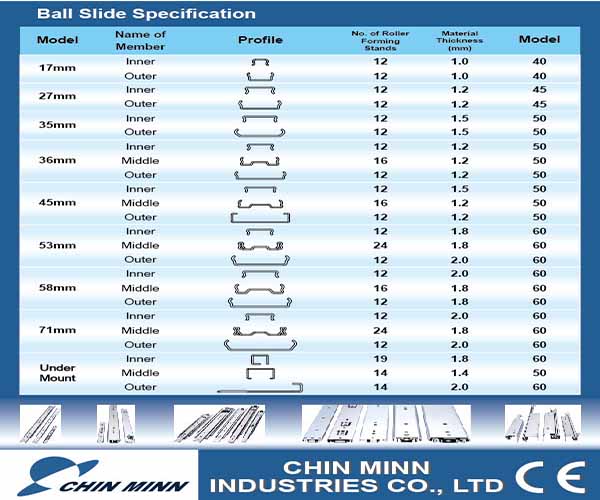

Chin Minn is the professional automation solutions equipment manufacturer from Taiwan. We committed to three main kinds of drawer slides roll forming machine: Standard, Heavy duty, and multiple stands hole punch type to roll form various types of slide rail such as 2-fold ball bearing slide, full extension telescopic channel slides, drawer runner, steel ball slide, server rack slide rail and hidden slides etc. The roll forming equipment of drawer channel and servo slide production lines is customized according to specific requirements. Our experienced engineers contribute passion in developing unsurpassed drawer slide roll form machines and roll forming techniques to satisfied customers from all over the world.

This heavy duty type ball bearing drawer slide roll forming machine is able to roll form drawer slides profile with tight tolerance. Also, punch and cut-off unit can punch all flat holes on drawer slides. ChinMinn precisely calibrates roll forming system with the finest instruments and authorized operators for high quality roll forming equipment manufacturing. This heavy duty drawer slide machine is widely used in producing furniture fittings and hardware for kitchen cabinets, office supplies, and furniture appliance. Chin Minn offers customized slides making machine design and manufacturing according to customers' drawer channel slides profile, design, and requirements. ChinMinn's high quality slides make roll forming machine makes slide rail manufacturing fast, smooth, and easy.

The demand of undermount drawer slides is increasing for fine crafted wooden furniture and cabinets. The roll forming techniques of undermount, hidden, concealed drawer runners are more complicated than standard steel ball slides. However, Chinminn is able to customize undermount drawer slides and ball bearing server rack slide roll forming equipment and multiple stands hole punching for saving time and cost.

More product info, please contact us~

Specification:

| Major Components | Quantity | |

| 1 | Machine Base | 1 set |

| 2 | Roll Forming Stand | 10 ~ 25 stands |

| 3 | Roll Forming Speed | 3 ~ 10 meters |

| 4 | Automatic Punch and Cut-off Unit | 1 set |

| 5 | Punch and Cut-off Die | 1 set |

| 6 | Hydraulic Power Pack | 1 set |

| 7 | Coolant system | 1 set |

| 8 | Single Head Decoiler | 1 set |

| 9 | Length Cut-off Device | 1 set |

| 10 | Rail leaving device | 1 set |

Product Videos:

Related products

| Product | Pic | Description |

|

multiple hole punch roll forming machine

|

|

automatic hole punching stands |

| cassette type roll forming machine |  |

rollers, hole punching stand, and cut-off unit can be replaced. Sever rack slide rail roll forming system |

| semi-automatic drawer slides assembly machine |  |

two-section drawer slides assembly |

| automatic drawer slides assembly machine |  |

telescopic channel slides assembly |